Are you ready to witness the future of manufacturing? Look no further than manufacturing automation. This groundbreaking technology has completely transformed the way industries operate, revolutionizing efficiency and productivity like never before.

The Power of Manufacturing Automation

Manufacturing automation is a game-changer that utilizes advanced technologies such as robotics, artificial intelligence, and machine learning to streamline production processes. By automating repetitive tasks and optimizing workflows, it eliminates human error and significantly increases output speed.

Gone are the days when manual labor was required for every step of the manufacturing process. With automation in place, companies can now achieve higher levels of precision while reducing costs associated with labor-intensive operations.

Moreover, manufacturing automation enables businesses to scale their production capabilities effortlessly. Whether it’s mass-producing goods or customizing products according to individual customer preferences, this technology empowers industries to meet diverse demands efficiently.

Solidot Electronic Technology: Leading the Way

In the realm of manufacturing automation pioneers stands Solidot Electronic Technology – a company at the forefront of innovation. With its cutting-edge solutions tailored specifically for various industries, Solidot has set new benchmarks in terms of efficiency and quality.

By integrating state-of-the-art robotic systems into their clients’ factories, Solidot has successfully optimized production lines across multiple sectors. Their expertise lies not only in developing customized automated solutions but also in providing comprehensive training programs that empower employees to adapt seamlessly to these transformative changes.

Solidot’s commitment towards sustainable practices is another reason why they have become an industry leader. Through energy-efficient designs and waste reduction strategies implemented within their automated systems, they contribute significantly towards building a greener future for manufacturing industries worldwide.

The Role of IO Modules in Manufacturing Automation

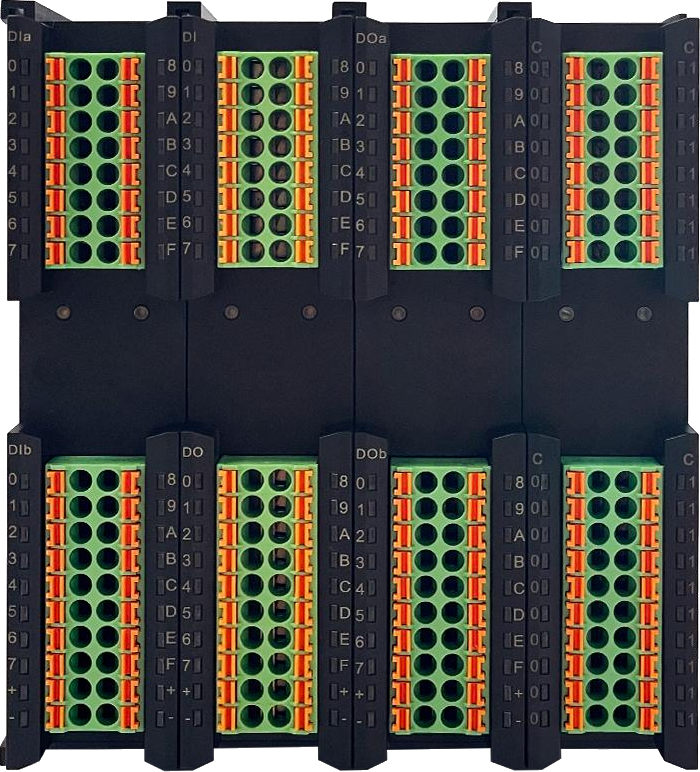

io modules, also known as input-output modules, play a crucial role in the success of manufacturing automation. These devices act as intermediaries between sensors and actuators, facilitating seamless communication within automated systems.

By connecting various components of the production line, IO modules enable real-time data exchange and control over different processes. This ensures that every aspect of the manufacturing operation is synchronized and optimized for maximum efficiency.

Furthermore, IO modules provide flexibility by allowing easy integration with existing machinery. Whether it’s retrofitting an older system or expanding an automated setup, these modules simplify the process while minimizing downtime.

The Future is Automated

In conclusion, manufacturing automation has revolutionized industries worldwide by enhancing productivity, precision, and scalability. Companies like Solidot Electronic Technology are leading this transformation through their innovative solutions tailored to specific industry needs.

With technologies such as robotics and AI continuing to advance at a rapid pace, we can expect even greater advancements in manufacturing automation in the future. Embracing this revolution will undoubtedly propel businesses towards unprecedented levels of success while shaping a more efficient and sustainable world for generations to come.