In today’s fast-paced manufacturing industry, businesses are constantly seeking ways to improve efficiency and precision in their operations. One technology that has revolutionized the way machines operate is the servo drive system.

The Power of the Servo Drive System

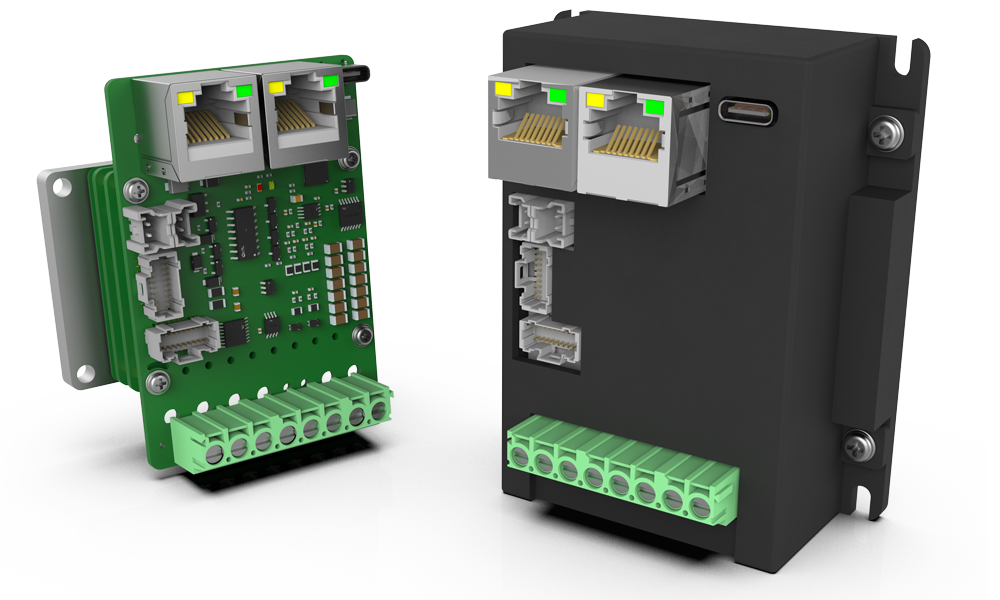

The servo drive system is a sophisticated control mechanism that enables precise movement and positioning of machinery. It consists of three main components: a motor, an encoder, and a controller. The motor converts electrical energy into mechanical motion, while the encoder provides feedback on position and speed. The controller processes this information to ensure accurate movement according to predefined parameters.

This advanced system offers numerous benefits for manufacturers. Firstly, it allows for high-speed operation with exceptional accuracy, resulting in improved productivity and reduced cycle times. Secondly, its closed-loop control ensures consistent performance even under varying load conditions or external disturbances. Lastly, the servo drive system enables seamless integration with other automation technologies such as robotics or conveyor systems.

Leadshine: A Leader in Servo Drive Systems

When it comes to reliable and high-performance servo drive systems, Leadshine stands out as a trusted provider in the industry. With years of experience and expertise in motion control solutions, Leadshine offers a wide range of products tailored to meet diverse manufacturing needs.

Leadshine’s servo drives are known for their exceptional precision and reliability. They incorporate advanced algorithms that optimize torque output while minimizing vibration or resonance issues commonly encountered in industrial settings.

Beyond their technical excellence, Leadshine also prioritizes customer satisfaction by offering competitive pricing strategies without compromising quality standards. This approach makes them an ideal choice for businesses looking to enhance their production capabilities while maintaining cost-efficiency.

Elevating Control with PLC Remote IO

In addition to servo drive systems, another crucial component in industrial automation is plc remote io. This technology allows for the seamless exchange of data between various devices and sensors, enabling centralized control and monitoring.

PLC remote IO offers several advantages for manufacturers. It simplifies wiring complexity by reducing the need for extensive cabling throughout the facility. Furthermore, it enhances flexibility as additional input/output modules can be easily added or reconfigured without disrupting operations.

By integrating a servo drive system with PLC remote IO, manufacturers can achieve enhanced precision and efficiency across their entire production line. The combination of these technologies enables real-time communication and synchronization between different machines, resulting in optimized performance and reduced downtime.

Conclusion

The servo drive system has revolutionized manufacturing processes by providing precise motion control capabilities that enhance efficiency and productivity. Leadshine’s expertise in this field ensures reliable solutions at competitive prices, empowering businesses to stay ahead in today’s competitive market.